-

Application of Stainless Steel Strip in Electronic Information Industry

Stainless steel strips have many applications in the electronic information industry, as follows: 1. Electronic device structural components: Shell and frame: Stainless steel strips have good strength and rigidity, providing a sturdy shell and frame structure for electronic devices, protecting internal electronic components from external impact and damage. For example, the casings of mobile

2024-11-07 -

What are the applications of stainless steel strips in the chemical industry

Stainless steel strips are widely used in the chemical industry, as follows: 1. Manufacturing of chemical equipment: Reactor: Various chemical reactions in chemical production need to be carried out inside the reactor, and stainless steel strips can be used to manufacture reactor tanks, stirrers, and other components. For example, in some high-temperature, high-pressure, and highly corrosiv

2024-10-30 -

Advantages and disadvantages of three polishing methods for stainless steel belts

There are three commonly used polishing methods for stainless steel strips: mechanical polishing, chemical polishing, and electrochemical polishing, each of which has its own advantages and disadvantages.

2022-07-25 -

What is the difference between cold rolling and hot rolling of stainless steel

1. Different production processes Stainless steel hot rolling is rolled above the recrystallization temperature of the metal material, and stainless steel cold rolling is rolled below the recrystallization temperature of the metal material, and each metal material has its own recrystallization temperature. crystallization temperature.

2022-07-25 -

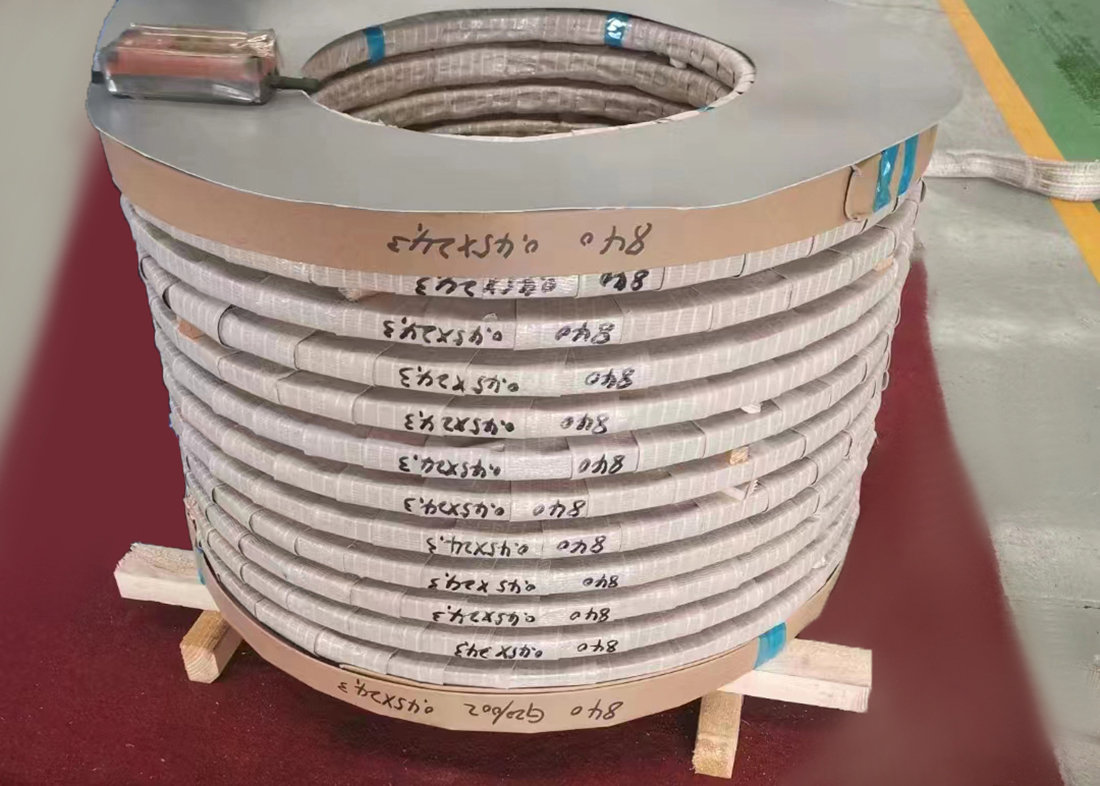

Application of stainless steel coil in several major industries

Stainless steel coil is one of the important stainless steel sheets. According to the different production processes, it can be divided into two categories: cold-rolled stainless steel coil and hot-rolled stainless steel coil, and according to different materials, it can be divided into austenite, Stainless steel coils in ferritic, martensitic and duplex materials. Like other types of stainless st

2022-07-25 -

What should be paid attention to when processing stainless steel plate

When machining stainless steel, adding cooling lubricant can actually reduce the cutting heat and cutting force during the cutting process to a large extent. In this regard, we actually need to focus on its ignorance to a large extent in order to prolong the life of the tool and on the other hand to ensure the smoothness of the stainless steel sheet product.

2022-07-25

- 08-192025

Why is stainless steel coil used for the shell of large storage tanks

The shell of large storage tanks is made of stainless steel coils, which are designed to meet the core requirements of "long-term storage, safe pressure bearing, and adaptability to various media" by utilizing their characteristics of corrosion resistance, good formability, stable strength, and easy maintenance, especially for harsh storage environments such as corrosion, high temperature, and hyg

- 08-122025

What is the cold rolling process for stainless steel strip

The cold rolling process of stainless steel strip is the process of rolling and processing the hot-rolled stainless steel strip at room temperature to obtain higher dimensional accuracy, better surface quality, and specific mechanical properties. Its process is complex and requires strict equipment and operation. The specific process is as follows:

- 08-062025

What are the applications of stainless steel coils in the chemical industry

Stainless steel coils are widely used in various equipment manufacturing, pipeline systems, container lining and other scenarios in the chemical industry due to their excellent corrosion resistance, high temperature resistance, strength and processability. They are the core material for dealing with complex media (such as acids, alkalis, salts, organic solvents, etc.) and harsh working conditions

- 07-292025

What are the performance advantages of stainless steel strips

Stainless steel strip is a strip product made from stainless steel through rolling, slitting and other processes. With its unique material properties and processing performance, it is widely used in many fields. Its performance advantages are mainly reflected in the following aspects:

- 07-222025

What is the wear resistance of stainless steel coils

The wear resistance of stainless steel coils is not fixed, but depends on their alloy composition, microstructure, surface state, and specific usage environment (such as friction mode, load size, medium corrosiveness, etc.). Overall, it presents a "moderate to high" characteristic, and there are significant differences among different models. The following is a specific analysis from two aspects:

WeChat ID:www.chengguosheying.com

WeChat ID:www.chengguosheying.com

Add WeChat

Add WeChat

Contact us

Contact us

The phone

The phone