Intimate service comes from the recognition of customers, and proposes high-quality product matching solutions according to customer needs

Product quality comes from rigorous and perfect quality control, and every step is full of our strict sense of responsibility

Exclusive customization comes from personalized configuration solutions, timely and efficient supporting new product development and production

Fast distribution originates from sufficient inventory + processing + fast logistics, and upholds enthusiastic and efficient management

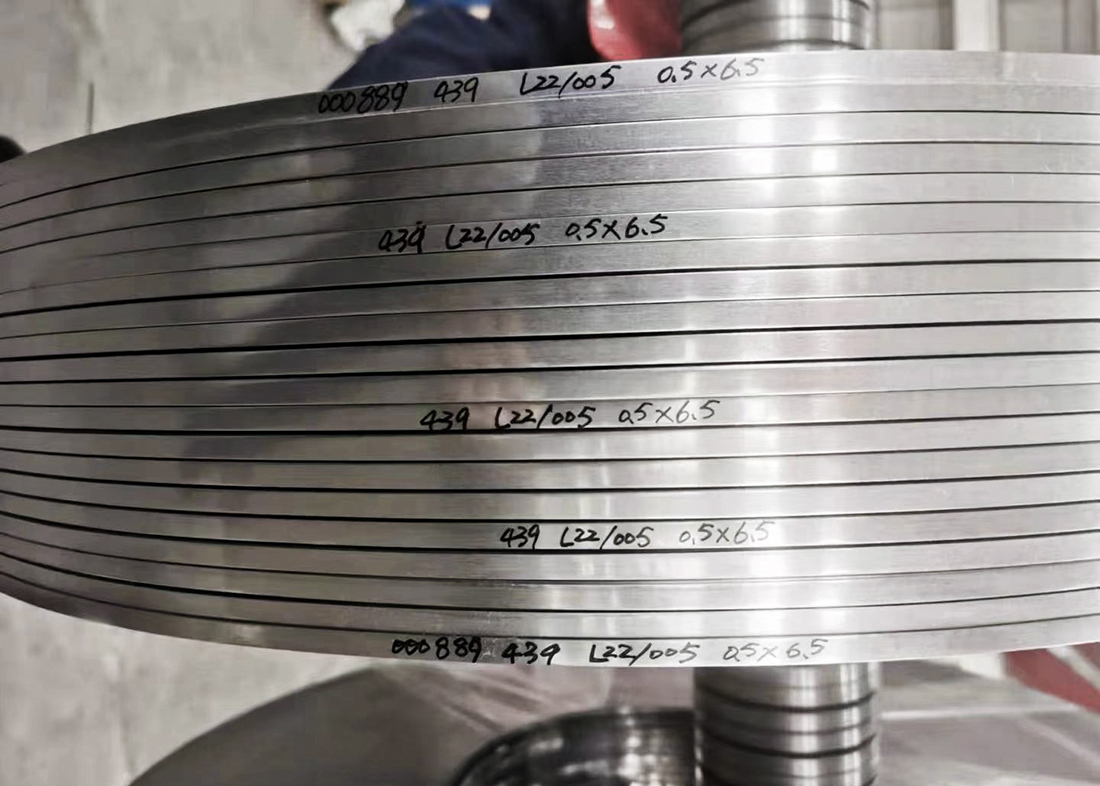

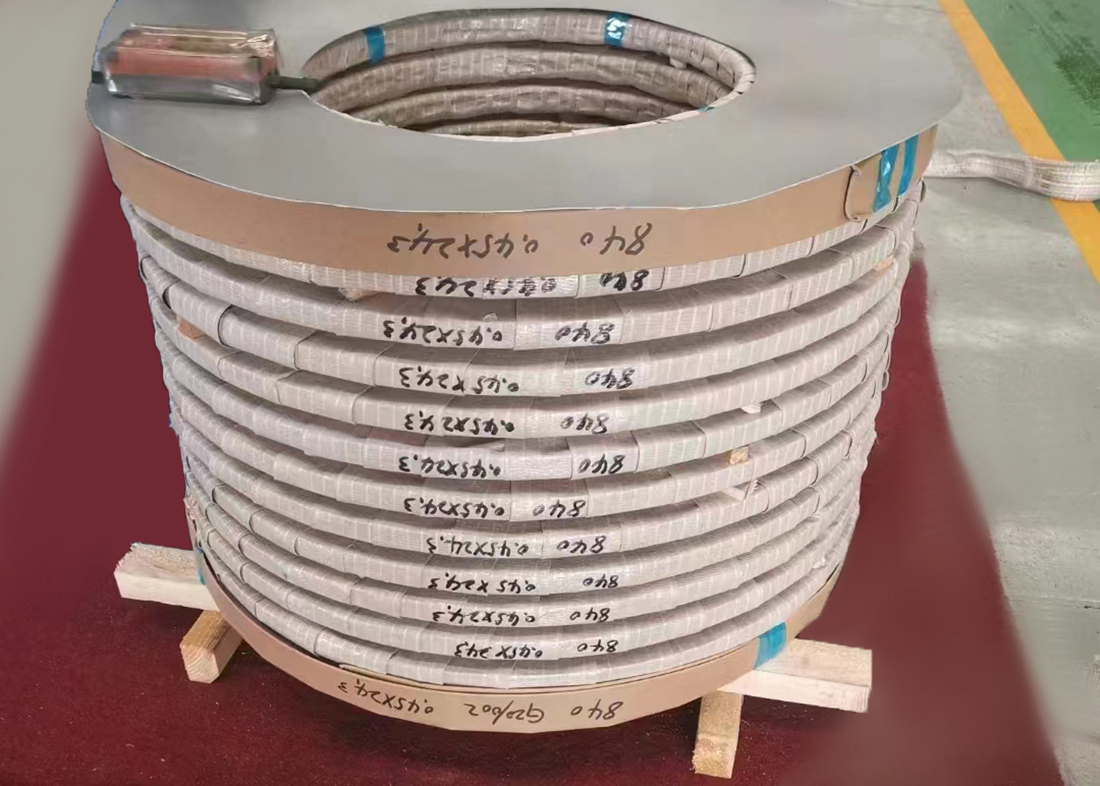

From raw material detection to warehousing registration management, to ensure the overall quality of products

From surface treatment to standard comparison

From material cutting and processing control to re-inspection, packaging and delivery

Every step is full of our strict sense of responsibility

Special material stainless steel is mainly produced with a thickness of 0.02mm-3.1mm and a width of 1mm-1500mm

Relying on the company's domestic and foreign processing equipment and logistics network throughout the country

From customer orders to fit stock screening

Then to processing, production, re-inspection and distribution

Our R&D team has established good cooperative relations with domestic and foreign steel mills

Timely and efficient cooperation with customers for product development

Combined with a Japanese-funded continuous electroplating factory, we have successfully launched gold-plated, silver-plated, nickel-plated and other electroplating products.

Products have broad market prospects and development potential

The shell of large storage tanks is made of stainless steel coils, which are designed to meet the core requirements of "long-term storage, safe pressure bearing, and adaptability to various media" by utilizing their characteristics of corrosion resistance, good formability, stable strength, and easy maintenance, especially for harsh storage environments such as corrosion, high temperature, and hyg

The cold rolling process of stainless steel strip is the process of rolling and processing the hot-rolled stainless steel strip at room temperature to obtain higher dimensional accuracy, better surface quality, and specific mechanical properties. Its process is complex and requires strict equipment and operation. The specific process is as follows:

Stainless steel coils are widely used in various equipment manufacturing, pipeline systems, container lining and other scenarios in the chemical industry due to their excellent corrosion resistance, high temperature resistance, strength and processability. They are the core material for dealing with complex media (such as acids, alkalis, salts, organic solvents, etc.) and harsh working conditions

Stainless steel strip is a strip product made from stainless steel through rolling, slitting and other processes. With its unique material properties and processing performance, it is widely used in many fields. Its performance advantages are mainly reflected in the following aspects:

The wear resistance of stainless steel coils is not fixed, but depends on their alloy composition, microstructure, surface state, and specific usage environment (such as friction mode, load size, medium corrosiveness, etc.). Overall, it presents a "moderate to high" characteristic, and there are significant differences among different models. The following is a specific analysis from two aspects:

The durability performance of stainless steel strip is good, which is closely related to its material characteristics, processing technology, and usage environment. This is reflected in the following aspects, and the durability in different scenarios will also be affected by certain factors:

Stainless steel coils are widely used in various equipment manufacturing, pipeline systems, container lining and other scenarios in the chemical industry due to their excellent corrosion resistance, high temperature resistance, strength and processability. They are the core material for dealing with complex media (such as acids, alkalis, salts, organic solvents, etc.) and harsh working conditions

1. Different production processes Stainless steel hot rolling is rolled above the recrystallization temperature of the metal material, and stainless steel cold rolling is rolled below the recrystallization temperature of the metal material, and each metal material has its own recrystallization temperature. crystallization temperature.

The shell of large storage tanks is made of stainless steel coils, which are designed to meet the core requirements of "long-term storage, safe pressure bearing, and adaptability to various media" by utilizing their characteristics of corrosion resistance, good formability, stable strength, and easy maintenance, especially for harsh storage environments such as corrosion, high temperature, and hyg

The cold rolling process of stainless steel strip is the process of rolling and processing the hot-rolled stainless steel strip at room temperature to obtain higher dimensional accuracy, better surface quality, and specific mechanical properties. Its process is complex and requires strict equipment and operation. The specific process is as follows:

Stainless steel strip is a strip product made from stainless steel through rolling, slitting and other processes. With its unique material properties and processing performance, it is widely used in many fields. Its performance advantages are mainly reflected in the following aspects:

The wear resistance of stainless steel coils is not fixed, but depends on their alloy composition, microstructure, surface state, and specific usage environment (such as friction mode, load size, medium corrosiveness, etc.). Overall, it presents a "moderate to high" characteristic, and there are significant differences among different models. The following is a specific analysis from two aspects:

The durability performance of stainless steel strip is good, which is closely related to its material characteristics, processing technology, and usage environment. This is reflected in the following aspects, and the durability in different scenarios will also be affected by certain factors:

In the manufacturing process of photovoltaic equipment, stainless steel coils have become one of the key materials due to their excellent corrosion resistance, mechanical strength, processing performance, and stability, and are widely used in equipment structural components, carriers, precision parts, and other scenarios. The specific reasons and application scenarios are as follows:

WeChat ID:www.chengguosheying.com

WeChat ID:www.chengguosheying.com